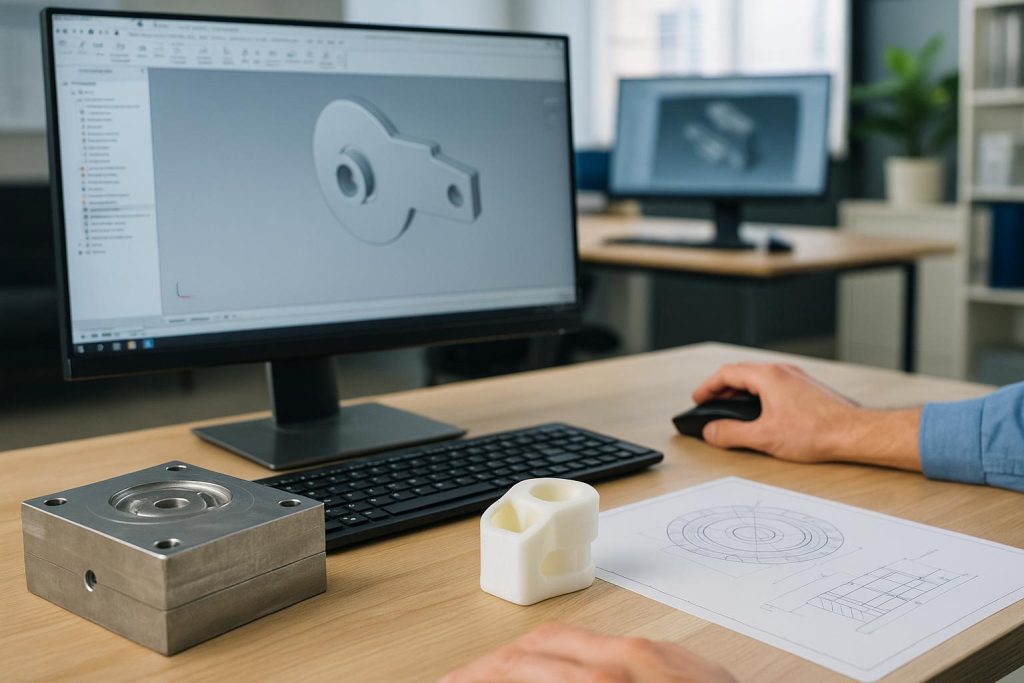

Our in-house tooling department delivers precision-engineered injection molds and custom fabrication solutions tailored to complex production requirements. From initial design through maintenance and refurbishment, every tool is crafted to meet strict quality and performance standards. Supported by advanced CAD/CAM technology and a rigorous quality assurance process, we ensure consistency, durability, and efficiency across all tooling operations

- Injection Mold Tooling

- Custom Fabrication

- Maintenance & Refurbishment

- CAD/CAM & Quality Assurance